Designing LEGO models using software like BrickLink Studio, LEGO Digital Designer (LDD), and Mecabricks is an excellent way to plan intricate builds before purchasing bricks. However, many builders make common mistakes that lead to frustration when transitioning from digital design to real-world LEGO creations. In this guide, we’ll cover the top LEGO design mistakes and how to avoid them for a smoother building experience.

1. Ignoring Structural Stability

The Problem:

In LEGO software, there’s no gravity or friction, meaning models may look stable but collapse when built physically due to weak connections or poor weight distribution.

How to Avoid It:

Use LEGO Technic elements to reinforce joints and load-bearing areas.

Build prototypes of critical sections to test structural integrity.

Balance weight properly, ensuring heavier bricks are positioned lower.

2. Using Illegal Building Techniques

The Problem:

Some software tools allow connections that are impossible or too fragile in reality, including:

Overly tight connections that put stress on bricks.

Clipping or intersecting pieces that won’t fit properly.

Unsupported angled connections that aren’t physically possible.

How to Avoid It:

Follow official LEGO design standards for secure connections.

Physically test complex joints to ensure they work in reality.

Use BrickLink Studio’s stability check to identify weak spots.

3. Overcomplicating the Design

The Problem:

It’s easy to over-design in software, leading to fragile structures and difficult builds.

How to Avoid It:

Prioritize durability over extreme detailing to keep models practical.

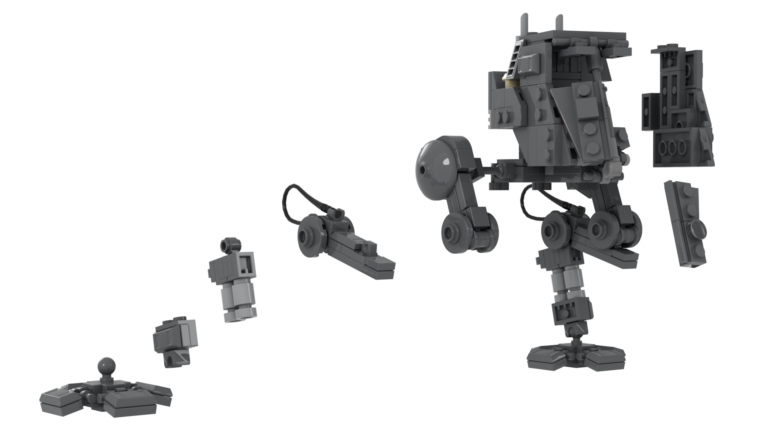

Use subassemblies to break the model into manageable parts.

Test complexity by building a physical version before finalizing.

4. Ignoring LEGO Part Availability and Colors

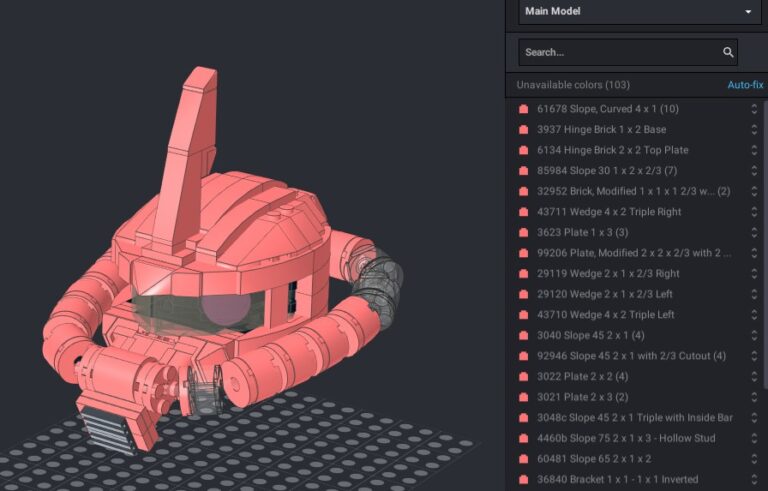

The Problem:

LEGO software includes every brick in every color—even those not available in real life.

How to Avoid It:

Use BrickLink’s database to verify real-world part availability.

Stick to widely available colors to ensure easy sourcing.

Be flexible with color choices if certain pieces are rare or expensive.

5. Weak or Unsupported Joints

The Problem:

Some LEGO models depend on clips, ball joints, or hinges that may not support real-world movement or weight.

How to Avoid It:

- Reinforce moving parts by doubling up connection points.

- Choose friction-based joints for better support.

- Test articulation points early to prevent floppy or weak sections.

6. Designing Without Proper Scaling

The Problem:

Without a reference point, models might be too large or too small when built.

How to Avoid It:

- Compare the model to a LEGO minifigure or standard brick for accurate scaling.

- Use measurement tools within the software to maintain proportion.

- Consider display and storage space when determining final size.

7. Not Planning for LEGO Instruction Creation

The Problem:

A digital LEGO model may be easy to assemble virtually but nearly impossible to build step-by-step in real life due to overlapping parts or unclear sequences.

How to Avoid It:

- Plan logical subassemblies to make instructions easier to follow.

- Use software features to generate step-by-step build instructions.

- Manually test the build process to identify any problematic steps.

Conclusion

By avoiding these common LEGO design mistakes, you can create models that are structurally sound, realistic to build, and easy to assemble. Whether you’re designing a massive LEGO mech, a custom spaceship, or a detailed diorama, following these best practices will ensure your digital creations transition seamlessly to real-world builds.

Get More LEGO Design Tips!

Stay ahead of the game— stay updated for expert LEGO building techniques, design inspiration, and exclusive updates on our latest custom LEGO models!