Why I Use BrickLink Studio to Design My LEGO Creations

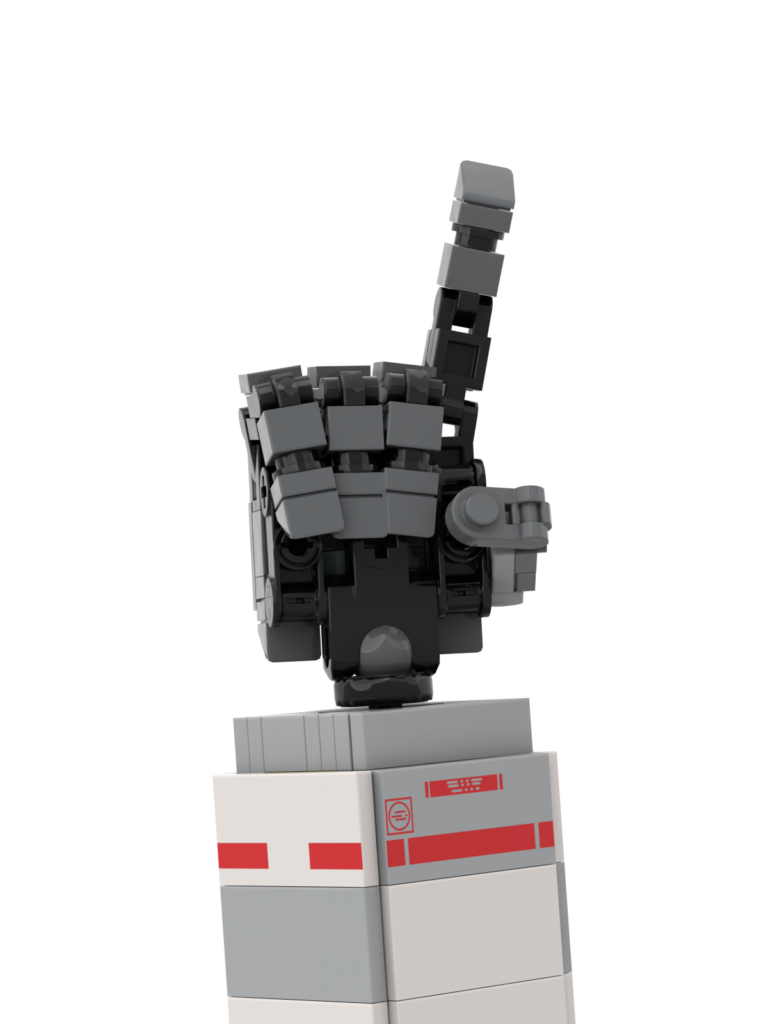

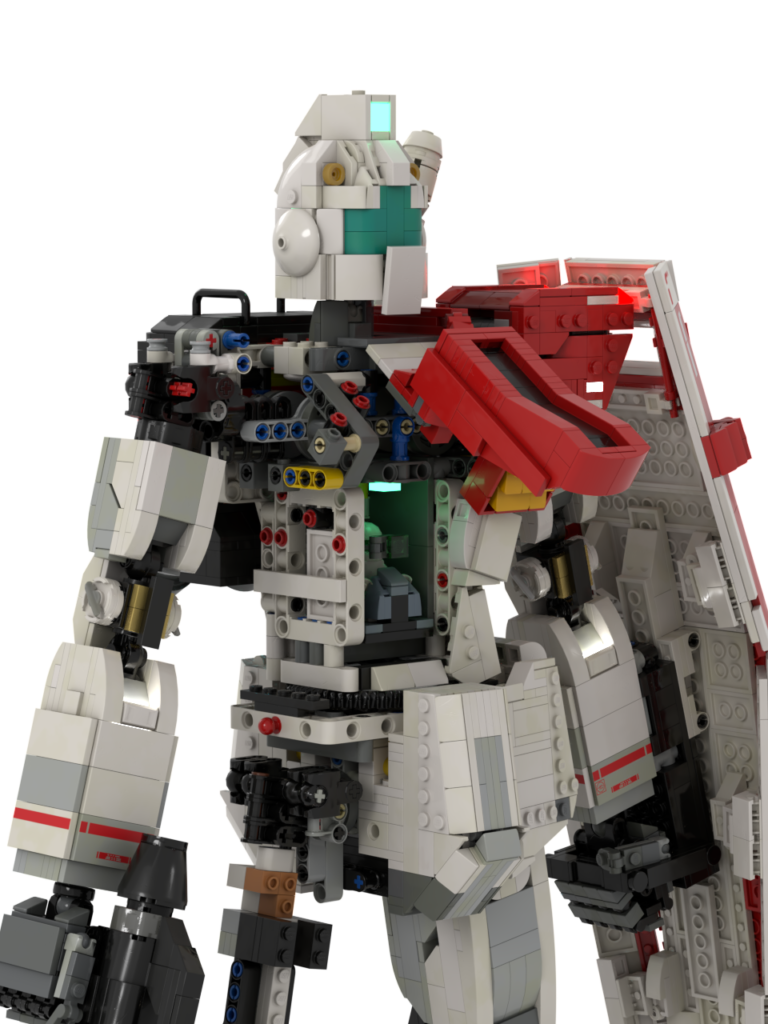

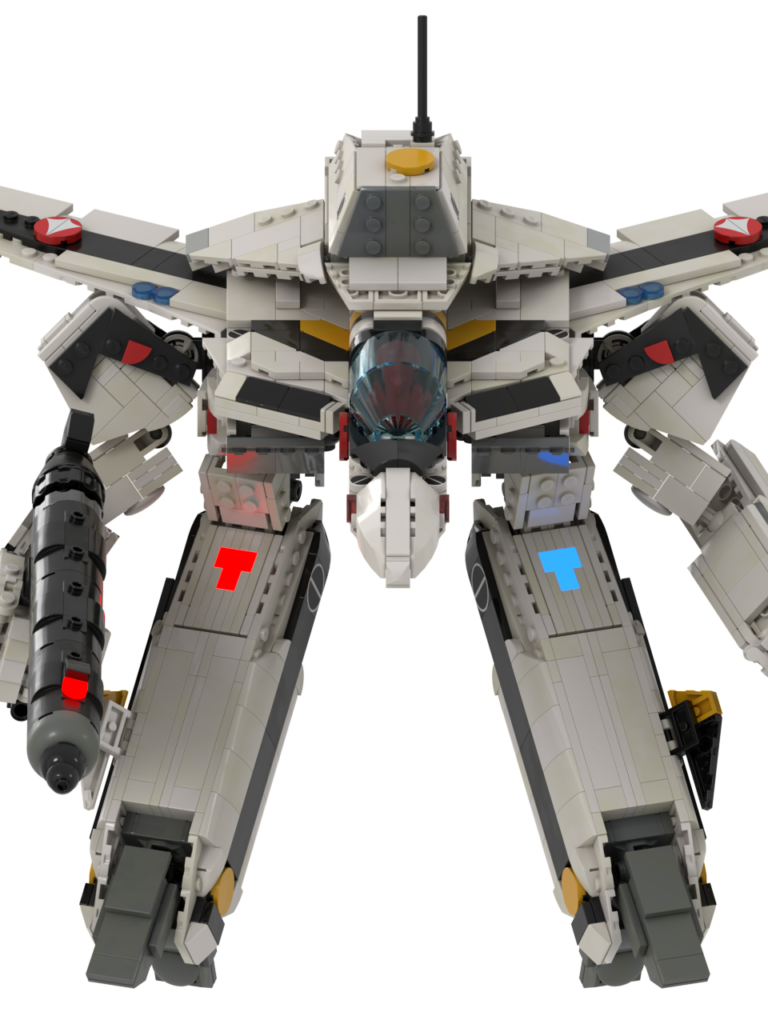

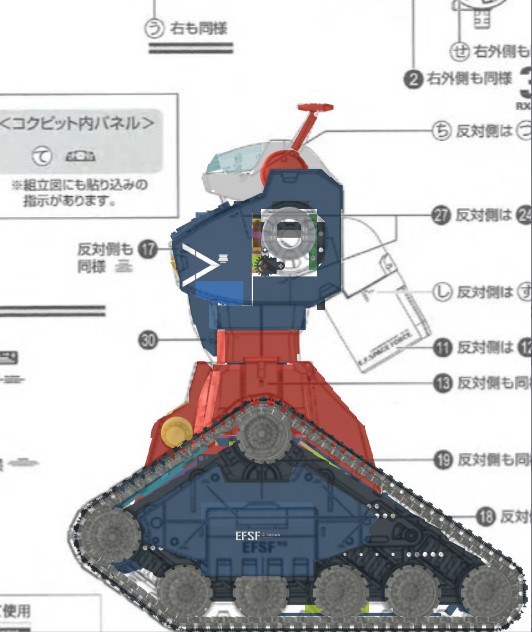

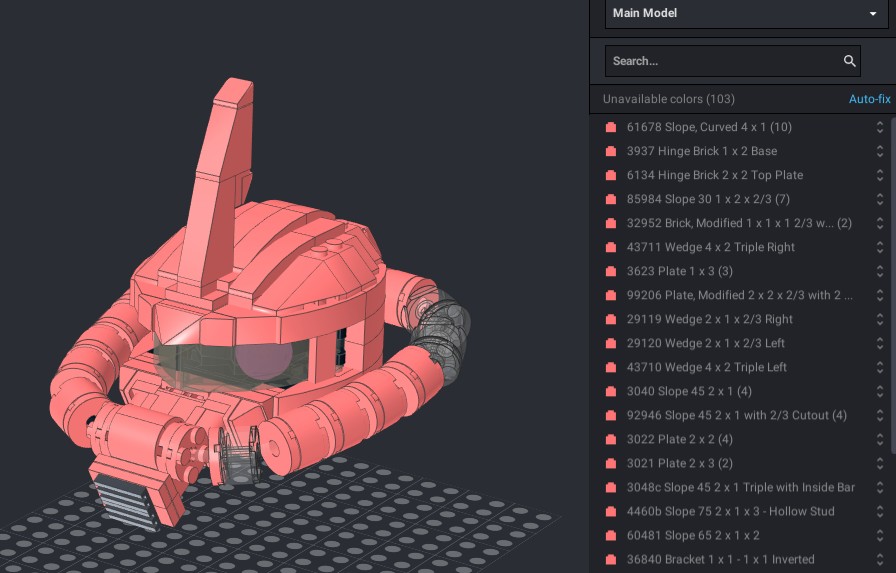

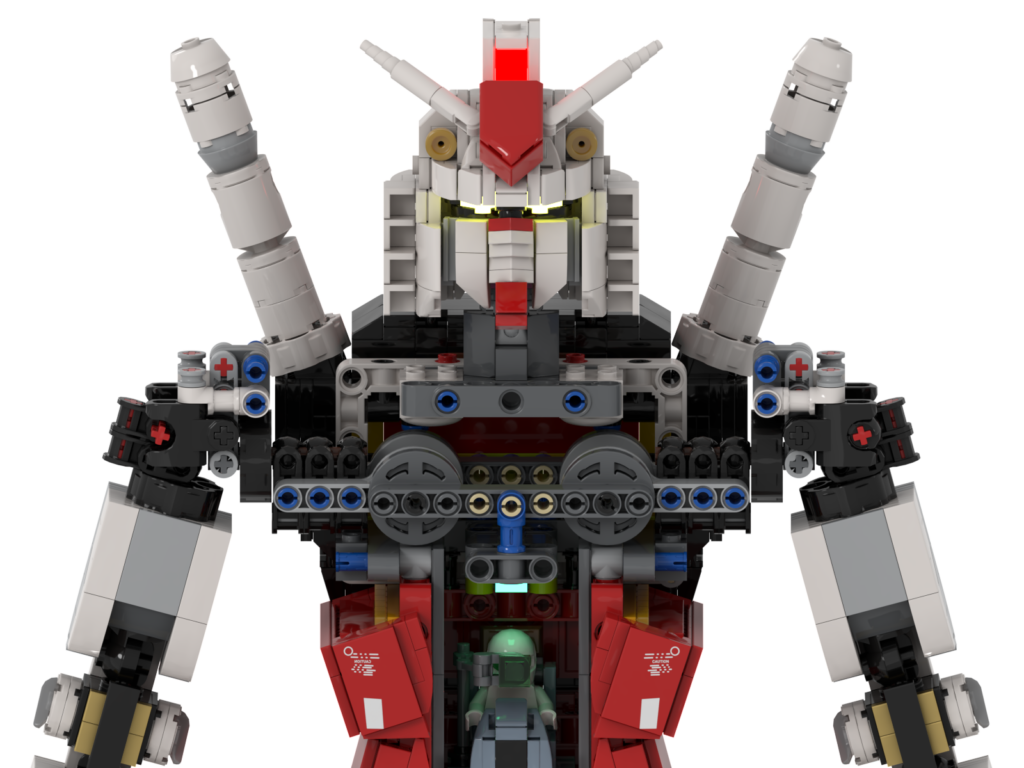

When it comes to designing custom LEGO creations, choosing the right digital tool is essential. For me, that tool is BrickLink Studio—a powerful and free LEGO design software that lets builders plan, visualize, and refine their models before ever touching a physical brick. In this article, I’ll explain why BrickLink Studio is my go-to platform for building everything from LEGO giant robots to detailed architectural models. If you’re serious about LEGO digital design, keep reading to discover how BrickLink Studio can elevate your builds. 1. Intuitive and User-Friendly Interface Why It Matters: When you’re spending hours designing complex models, having a smooth and intuitive interface is a must. What I Love: Easy drag-and-drop functionality. Real-time snapping and alignment tools. A clean layout that doesn’t overwhelm. Whether you’re a beginner or an experienced builder, BrickLink Studio’s user interface makes the LEGO design process more enjoyable and efficient. 2. Massive LEGO Parts Library Why It Matters: You can’t build what you can’t find. BrickLink Studio includes an extensive LEGO parts database with almost every LEGO element available. What I Love: Accurate representations of real LEGO parts. Searchable categories and filters. Frequent updates to match the latest LEGO sets. This makes it easy to test ideas and stay creative without limitations. 3. Realistic Physics and Stability Tools Why It Matters: One of the main reasons I use BrickLink Studio is that it helps identify structural issues in LEGO builds before I start building in real life. What I Love: Collision detection prevents unrealistic overlaps. Built-in stability checker for analyzing weak connections. Ability to test different angles, poses, and positions. It doesn’t replace real-world testing, but it does help avoid major design flaws early on in the LEGO MOC (My Own Creation) process. 4. Integrated Instruction Maker Why It Matters: If you plan to share your designs or sell instructions, having a built-in LEGO instruction tool is a game changer. What I Love: Step-by-step instruction builder. Customizable layouts and views. Export to PDF for sharing or selling. This saves time and keeps everything in one place, especially useful for LEGO content creators. 5. Seamless Connection to BrickLink Marketplace Why It Matters: Once the design is finished, you’ll likely want to order parts. BrickLink Studio makes this step seamless. What I Love: Easy export of wanted lists. Direct upload to BrickLink.com. Automatic inventory comparison. This integration streamlines the transition from LEGO digital building to physical construction. 6. It’s 100% Free Why It Matters: Designing LEGO models digitally shouldn’t come with a price tag, especially for hobbyists. What I Love: No subscription fees. Free updates and support. High-quality features without the cost. Conclusion BrickLink Studio has completely transformed the way I design my LEGO creations. From its massive parts library and intuitive design tools to its built-in instruction maker and BrickLink integration, it’s the ultimate software for LEGO digital building. Whether you’re creating massive mechs, minifig-scale buildings, or functional display models, BrickLink Studio gives you the flexibility and power to bring your ideas to life with confidence. Want to Learn More About Digital LEGO Design? Check out my other articles for expert guides on: How to design stable LEGO models Bringing digital LEGO mechs to life Avoiding common LEGO design mistakes Start building smarter today with BrickLink Studio!